A Practical Way for Refineries to Lower ESG Risk

Environmental, Social, and Governance (ESG), first coined in 2005, is now at the forefront of investment decisions. Low ESG risk is a stability indicator for investors as customer and stakeholder beliefs continue to merge with their spending habits, signaling that sustainable investing is here to stay.

ESG, a Global Movement

Governments and standard-setting bodies around the world are working to define a set of global ESG standards that are focused on climate risk and greenhouse gas emissions reduction, as well as health and human safety.

In September 2020, the “group of five” CDP, Climate Disclosure Standards Board (CDSB), Global Reporting Initiative (GRI), International Integrated Reporting Council (IIRC) and Sustainability Accounting Standards Board (SASB), created a comprehensive ESG rating reporting system that supports the International Financial Reporting Standards Foundation (IFRS Foundation). The group of five are pushing policy makers to make these standards “compulsory rather than optional.”

And policy makers are listening. As of March 2021, the EU mandated sustainability disclosures in the financial sector to improve transparency. In the United States in March of 2021, the Securities Exchange Commission also created an enforcement task force focused on climate risk and ESG factors.

Under pressure from stakeholders, shareholders and the public, corporate governance managers at Occidental Petroleum Corp., Shell Oil, ExxonMobile and KinderMorgan are actively implementing ESG metrics into their business models as they work towards net-zero goals.

As refiners move to invest in green technology to offset their carbon footprints, Iron Creek Group’s technology offers a practical, streamlined way for oil and gas companies to modernize their waste-management processes: reducing climate risk, improving health and safety, and reducing the administrative burden of listing waste disposal.

Environmentally Sustainable Waste Management Processes

There are a variety of applications to treat refinery tank and process waste, but current practices like centrifugation, bioremediation, incineration, traditional thermal remediation and landfill disposal treatments all pose a risk to the environment and/or the health and safety of waste management teams and the public.

Iron Creek’s patented technologies are an environmental bright spot for the oil and gas industry, offering unparalleled treatment applications that are sustainable and safer than any other waste management process in the industry.

These technologies meet a list of ESG criteria and exceed the most stringent environmental regulatory requirements around the globe. As such, their technology has been deployed in Antarctica as well as the Arctic Circle, restoring these environments to their former pristine states.

When applied to the oil and gas industry, Iron Creek’s technology does the following to help lower climate risk and improve human health and safety:

Reduces carbon emissions and greenhouse gases

Recycles waste

Eliminates 100% of waste

Increases regulatory compliance

Improves efficiency

Reduces energy usage

Eliminates environmental liabilities

Improves operational safety

Improves long-term health and human safety

The patented designs finely control every step of the process, deploying elements from the waste to treat the contaminants or upcycle the materials into viable goods that can be sold to manufacturers.

Adopting Iron Creek Group’s technologies is a sure investment approach that can reduce environmental impact and lower risk while offering refineries efficient and cost-effective waste management systems.

Predictable Outcomes. Predictable Budgets.

For years, refineries have been investing in new technologies that reduce the environmental risk of their waste management processes. However, thus far, all of the waste-treatment technologies to treat tank and process waste pose risks to the environment or human health and safety (or both). These remedial technologies are inefficient and not cost effective in the long term. Iron Creek’s technologies bridge this gap and check a number of ESG criteria to help refineries better manage their risk.

ETC Technology

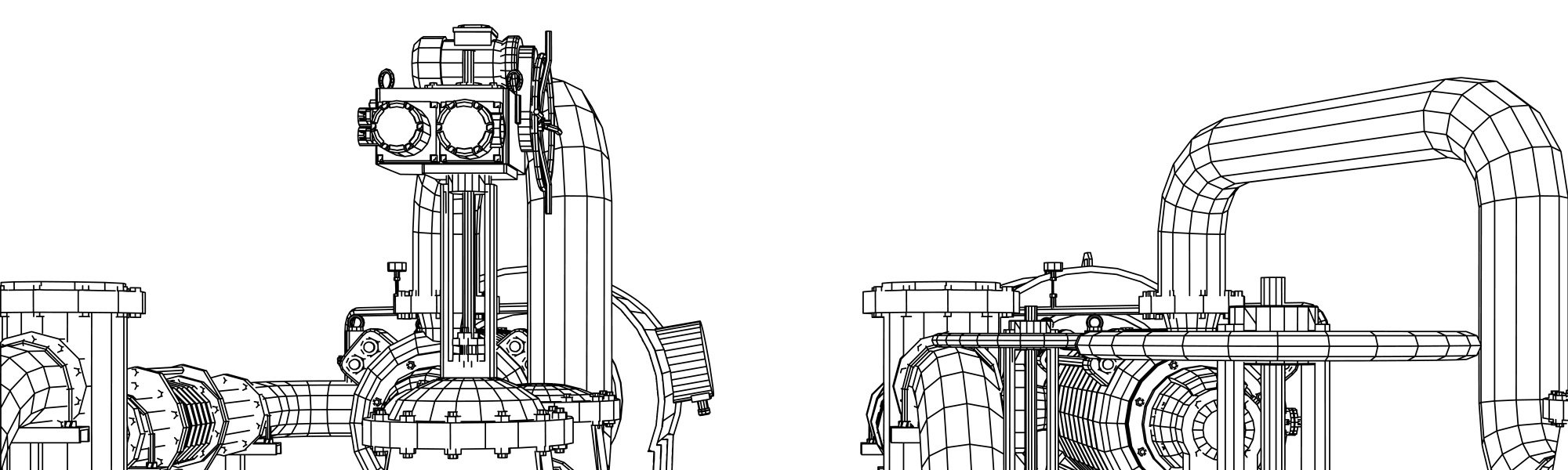

Enhanced Thermal Conduction (ETC) is a patented, award-winning remediation technology that treats hydrocarbon and organic waste onsite in a safe, static way that eliminates contingent liabilities, while reducing operating costs and carbon emissions. This innovative technology can be fueled by biomass, hydrogen, propane, electricity— or by the very hydrocarbon waste it’s treating.

ETC technology specializes in soil restoration, capturing contaminants and utilizing those elements to fuel the cleanup of impacted soil. It’s nimble, mobile and emergency-ready. The process eliminates 100% of waste while meeting stringent environmental regulations to restore land to residential standards.

ETC units are compact, yet scalable. They are proven to deliver results via fixed timelines and within fixed budgets, no matter the environment. As refineries move away from the bioremediation (or land farming) of tank sludge because the process pollutes the air, soil and water, ETC technology is a viable solution to restore land so it can safely be put to use.

Tech Zero Technology

Iron Creek’s patented Tech Zero technology offers refineries a streamlined, one-step, secondary-manufacturing process that recycles spent catalysts and tank process waste via zero oxygen conduction.

After treating tank and process waste, this next-generation technology results in two valuable products: higher-grade fuel that can be piped back into production and recycled metals or solids that are ready to be sold or reused.

This technology is designed to provide sustainable solutions to refineries looking for alternative waste-management applications.

Tech Zero gives refiners predictable outcomes and predictable budgets— all on fixed timelines. This unparalleled technology reduces the carbon footprint of the waste management process, improves operational safety, recycles 100% of refinery tank and process waste, promotes secondary revenue streams, reduces regulatory paperwork and increases turnaround time to improve productivity. Tech Zero can also be used to recycle oil booms, absorbents and more.

On-Site Risk Reduction Technology

Applying either or both of these technologies reduces regulatory paperwork while exceeding environmental regulations; increases environmental health and human safety; eliminates or recycles 100% of waste; eliminates contingent and future liability; and offers refineries a more efficient, cost-effective way to innovate their waste-treatment protocols. Further, the technology is emergency-ready to mitigate damage should a spill or leak occur.

When refineries modernize their tank waste management process, land application and/or landfilling procedures, they reduce the labor-intensive, administrative burden of listing waste.

Implementing ESG criteria not only lowers risk, but it improves valuation. Continued public, shareholder and stakeholder pressures are opening the door to new opportunities that will benefit refiners in the long-term. Iron Creek’s technologies are safe, predictable, practical and easy to implement— keys that will help refineries unlock more sustainable business practices and attract institutional investors.

ESG and the Bottom Line

Sustainable processes do not equate with loss of revenue. Implementing ESG criteria into corporate policy can help improve the bottom line. Written in 1995, and still relevant today, the Harvard Business Review published Green and Competitive: Ending the Stalemate, by Michael E. Porter and Claas van der Linde that aptly states,

"Like defects, pollution often reveals flaws in the product design or production process. Efforts to eliminate pollution can therefore follow the same basic principles widely used in quality programs: Use inputs more efficiently, eliminate the need for hazardous, hard-to-handle materials, and eliminate unneeded activities."

Adopting practices that regularly assess current protocols in an effort to improve production and reduce waste is just good business. As industries take steps to streamline their operations, while implementing mid and long-term sustainability initiatives, they protect their longevity, maintain their competitive advantage and increase their valuation.

According to PWC, “ESG represents risks and opportunities that will impact a company’s ability to create long-term value including climate change and resource scarcity.”

80% of studies show that stock price performance of companies is positively influenced by good sustainability practices.

There continues to be a high demand for petroleum-based fuels and products, which provides a massive opportunity for refineries to innovate their technology and update their policies to meet the expectations of the public, shareholders and stakeholders.

While change within heavily-regulated, multi-departmental industries takes time, Iron Creek Group makes it easy for refiners to adopt technology that will support innovation in a way that improves production, reduces waste and helps them exceed regulatory requirements.

About Iron Creek Group

Serving North America, Iron Creek Group specializes in developing innovative, nimble technology that solves complex environmental issues. Learn how they’re leveraging technology to challenge the existing remediation paradigm by visiting, https://www.ironcreekgroup.com

For questions and further information, please email Ken Bell: ken@ironcreekgroup.com.